BUILD & REPAIR TANGENTIAL FLOW SYSTEMS

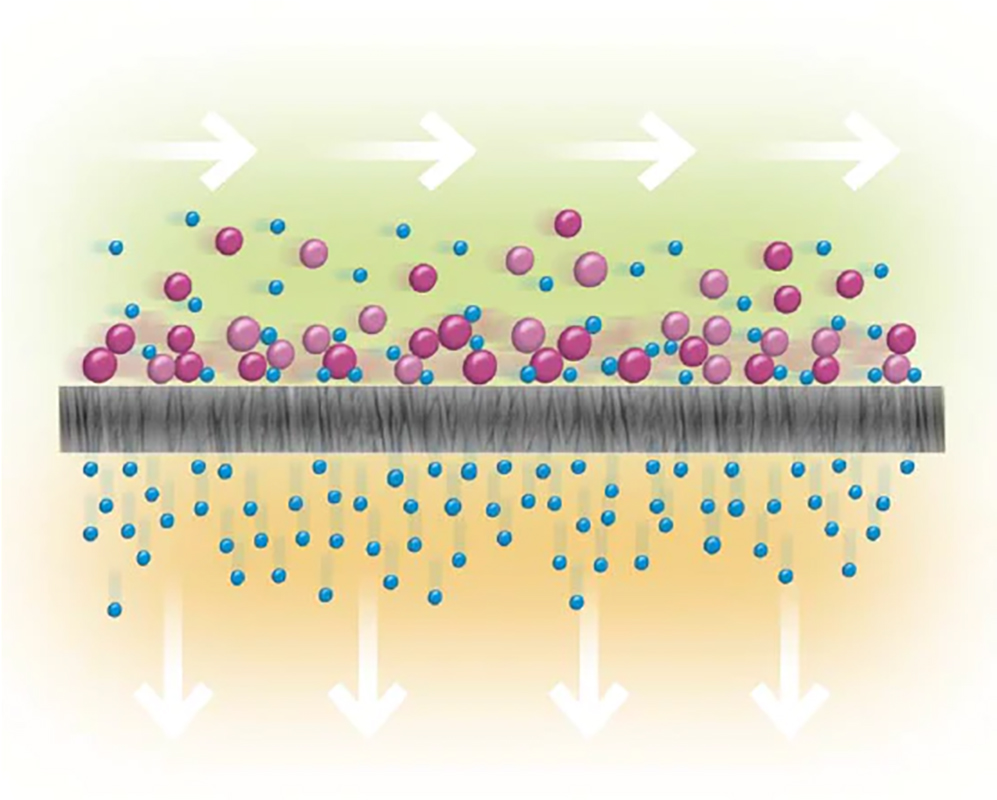

Tangential flow filtration (also known as crossflow filtration) is a filtration technique in which the starting solution passes tangentially along the surface of the filter. A pressure difference across the filter drives components that are smaller than the pores through the filter. Components larger than the filter pores are retained and pass along the membrane surface, flowing back to the feed reservoir.

Solution that is directed to the membrane surface is called the feed. Solution that passes along the membrane surface and back to the feed reservoir is the retentate. This solution is usually pumped back to the feed reservoir and recirculated. Solution that passes through the membrane is the permeate.

Tangential flow Filtration differs from normal flow filtration (also known as dead-end filtration or direct flow filtration) where the starting material is simply passed through a filter media. A key feature of tangential flow is the stream of fluid along the membrane surface that sweeps away the buildup of material on the filter surface and reduces fouling of the filter. In addition, retentate solution can easily be recirculated, allowing thorough processing of large volumes of solution.

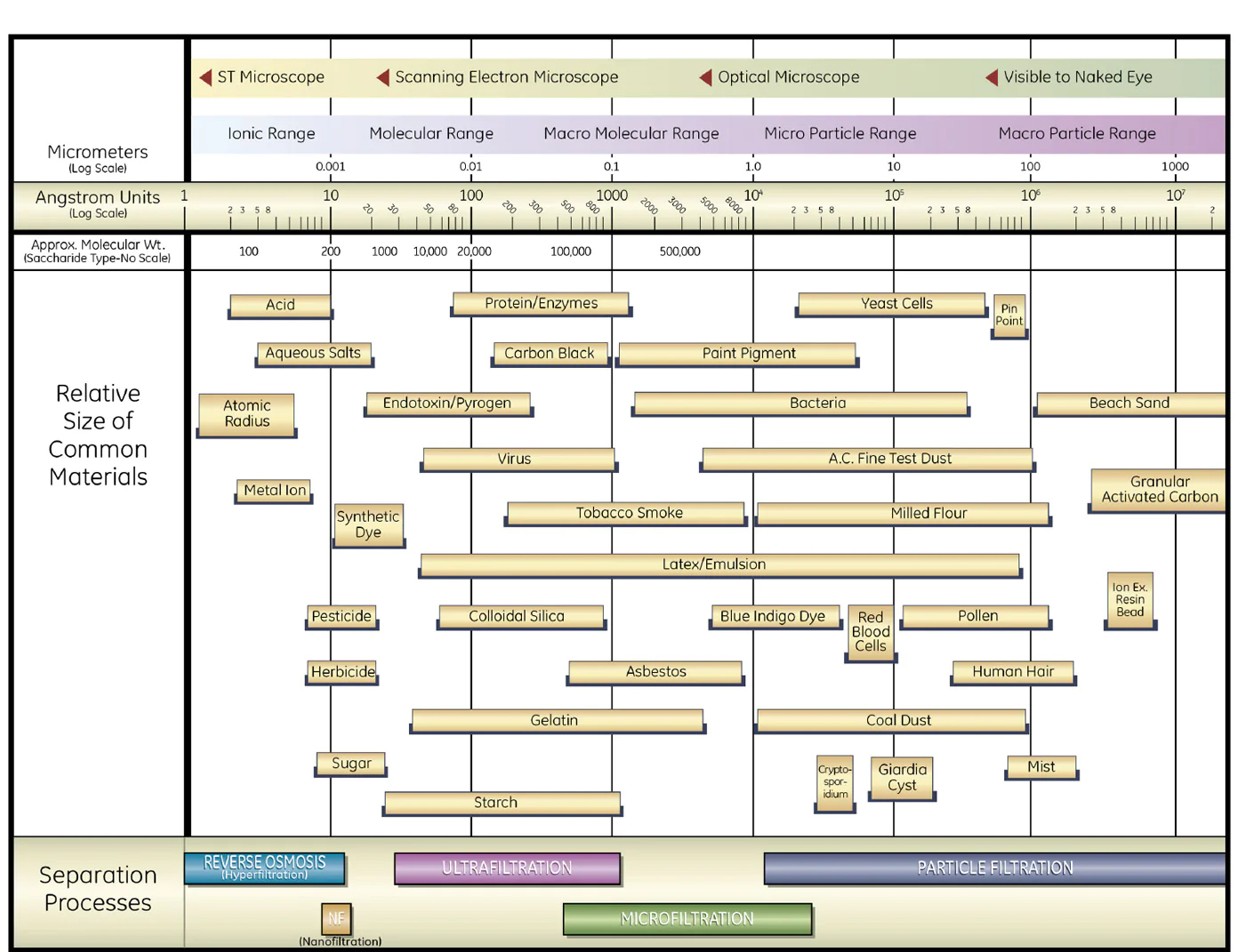

The size of the membrane used in tangential flow filtration dictates the depth of impurity removal. An ionic reverse osmosis membrane will separate water, alcohol and acetic acid from wine, selectively removing acetic acid and lowering volatile acidity. Molecular reverse osmosis isolates larger taint components, such as brettanomyces or volatile phenols from smoke contact, allowing for their removal without affecting the delicate flavor, aroma and color components of a wine. A larger, ultrafiltration pore size (10,000 – 100,000 molecular weight) provides opportunities to intensify red wine color or remove unwanted tints from white wines. Filtration providers uses the largest microfiltration membranes in commercial crossflow filtration.

FILTRATION & SEPARATION SPECTRUM

REQUEST A QUOTE

Ready to take the first step? By filling in the request below, we will begin the process of preparing a customized solution to your winemaking challenge. Our team of professionals is ready to share decades of wine production knowledge with you. We love a challenge! And will do our best to ensure you are realizing superior results.

Error: Contact form not found.